The Precision Way of Hardware - Key Components for Enabling Manufacturing

Hardware fittings, as an indispensable and important part of the modern industrial manufacturing system, undertake a variety of functions such as connection, transmission, support, decoration, etc., and play the role of “details determine success or failure” in many mechanical structures and end products. Since its establishment in 2010, Dongguan Zhenjun Metal Products Co., Ltd. has always been focusing on the precision manufacturing and innovative development of hardware accessories, with more than 30 years of industry accumulation, to provide customers with high-quality, customizable, international standards of hardware solutions, to help the global manufacturing industry to operate stably and continue to optimize.

hardware accessories: small volume contains large energy

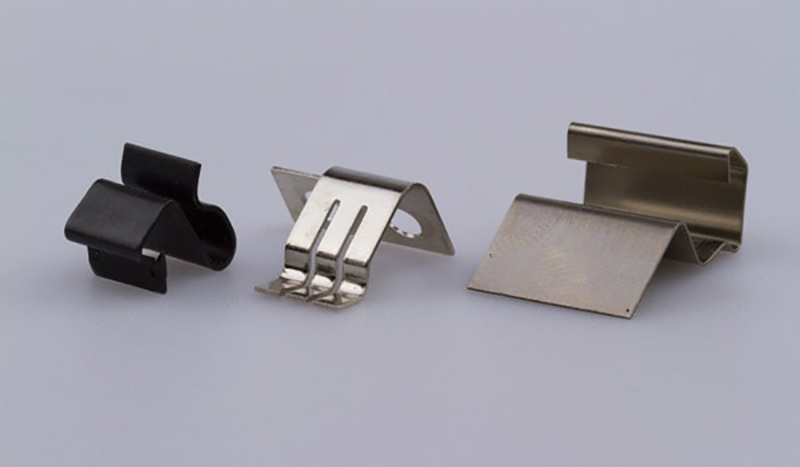

The so-called “hardware”, traditionally refers to gold, silver, copper, iron, tin five kinds of metal, but in the modern manufacturing context, hardware accessories refers to metal or alloy materials (such as stainless steel, aluminum alloys, copper alloys, zinc alloys, etc.) as the basis for the stamping, die-casting, machining, injection molding, welding and other processes to produce standard or non-standard parts, commonly used in construction and electronics, furniture, automotive, home appliances, medical and aviation industries. It is commonly used in various industries such as construction, electronics, furniture, automobile, home appliance, medical treatment, aviation and so on.

Although most of the hardware is simple in appearance and small in size, its role in the structure of the machine is crucial – a screw’s slippery teeth, a bracket error, a fastener’s looseness will often directly affect the stability and service life of the entire product. Therefore, “small hardware” is not only a test of craftsmanship, but also reflects the enterprise’s ability to strictly control the quality details.

Main classifications and functional applications

Hardware fittings cover a wide range of areas and can be broadly divided into the following categories according to function and structure:

1. Connection accessories: such as screws, nuts, rivets, washers, etc., used for connection and fixing between parts, widely used in machinery, electronics, assembly line and other scenes.

2. Structural support: such as brackets, bases, frames, commonly used in home appliances, medical equipment, photographic equipment and other products to ensure the stability of the structure.

3. Transmission parts: such as gears, bearings, drive shafts, couplings, etc., are the core components of power transmission, especially critical in industrial equipment and automotive field.

4. Decorative and functional parts: such as key shell, knob, decorative rings, shell panels, etc., these parts are not only functional, but also require a certain degree of aesthetics and feel experience.

5. Customized non-standard parts: designed and sampling production according to the customer’s product structure needs, suitable for new product development, small batch trial production or patented structural parts supporting.

Behind these hardware pieces, it is the embodiment of Zenjun’s deep understanding of craftsmanship and equipment precision guarantee. The company adopts advanced CNC machining equipment, automatic stamping system, precision die-casting technology, and is equipped with professional measuring tools to ensure that the tolerance, strength, and surface treatment of each piece of hardware meets customer standards.

Craftsmanship and quality: the two-wheel drive that determines the value of an accessory

The production process of hardware fittings seems to be simple, but in fact, it requires a very high level of craftsmanship. Zhenjun Metal always emphasizes that “technology is the core competitiveness”, and strictly controls the quality in many aspects, such as stamping, CNC machining, cold forging, milling and turning, automatic welding, surface treatment, and so on.

1. Mold Design: Precise mold structure directly determines the molding efficiency and product yield of stamping and die-casting. Zenith has in-house mold development capability, through three-dimensional modeling and mold flow analysis, to ensure that the mold design is scientific and reasonable, durable and efficient.

2. Precision processing capability: With the help of high-speed CNC lathe, automatic milling machine, rolling machine and other equipment, parts with high precision requirements are reprocessed, and the regular tolerance can be controlled within ±0.01mm.

3. Surface treatment process: according to customer needs to provide anodized, electroplated, sandblasted, baked paint, laser engraving, brushed and other treatments, not only to enhance the corrosion resistance of the parts, but also to enhance the product aesthetics and brand sense.

4. Comprehensive inspection system: Zhenjun has established a perfect incoming materials, production process, shipping inspection process, with the help of calipers, hardness testers, optical projectors, coordinate measuring instruments and other equipment, to provide customers with a full range of quality traceability.

In the manufacturing industry is increasingly intelligent, precision, high-end evolution of today, hardware accessories as the most basic but one of the most critical components, its manufacturing capacity is becoming an important embodiment of the comprehensive strength of enterprises. Dongguan Zhenjun Metal Products Co., Ltd. will continue to adhering to the “quality-oriented, innovation as the soul, customer first” concept, and constantly improve the manufacturing capacity of hardware, to create a more sophisticated, more reliable, more competitive metal solutions for customers around the world.