WHO WE ARE

Dongguan Zhenjun Metal Products Co. I have been in this business for more than 30 years of industry experience. The company has always adhered to the “quality-oriented, innovation as the soul, customer first” business philosophy, is committed to providing customers with high-quality metal products and customized solutions. After years of development, the company has become an influential manufacturer in the industry, the products are exported to domestic and overseas, widely used in photographic equipment, digital accessories, automotive accessories, household appliances, medical equipment, industrial equipment and other fields.

Translated with DeepL.com (free version)

WE OFFER

HIGH QUALITY METAL PRODUCTS AND CUSTOMIZED SOLUTIONS.

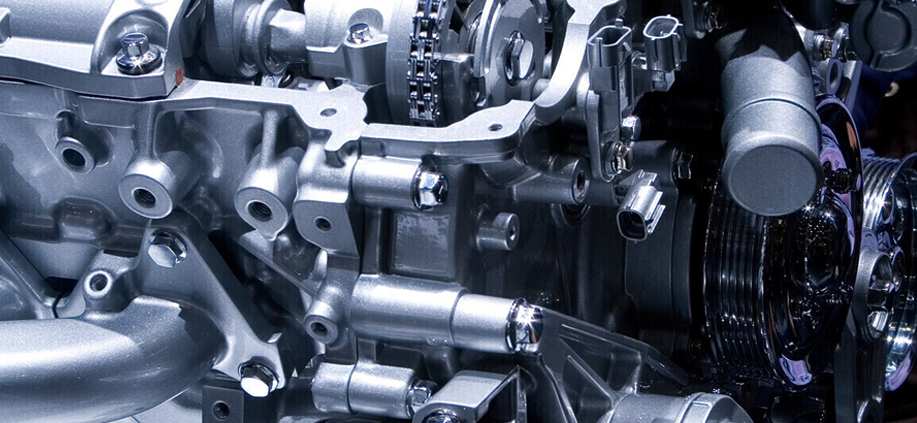

We are committed to providing you with high-quality metal products and customized solutions, which are widely used in photographic equipment, digital accessories, automotive accessories, household appliances, medical equipment, industrial equipment and other fields.

Aluminum, zinc alloy die-casting

Aluminum alloy and zinc alloy die casting, as one of the modern metal products manufacturing …

Hardware fitting

Hardware fittings, as an indispensable and important part of the modern industrial manufacturing system, undertake a …

Plastic products

Plastic products are products made of synthetic resin as the main raw material, processed by injection molding, extrusi…

Mold Design and Manufacturing

Moulds are special tools used in industrial production for mass production of parts and compon…

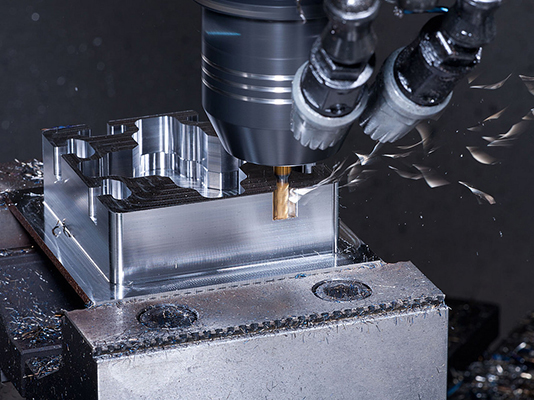

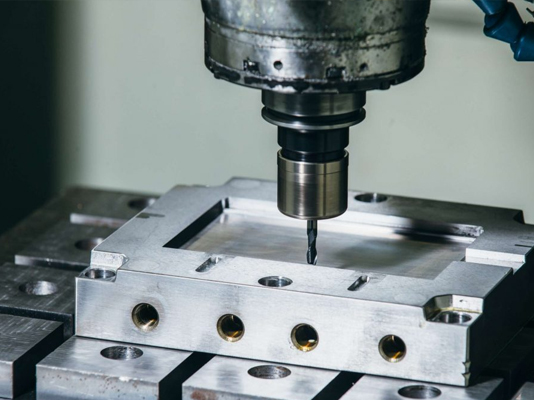

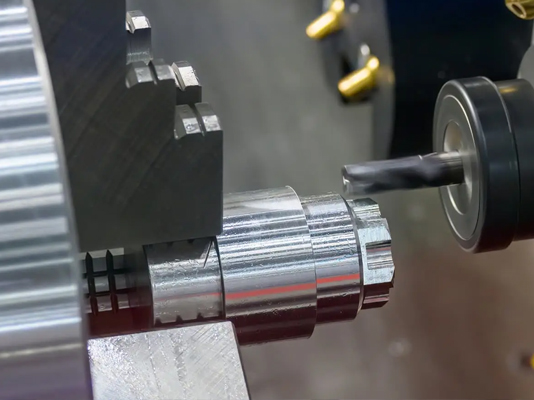

CNC Lathe

CNC lathe is a widely used automation equipment in modern machining, which belongs to high-precision…

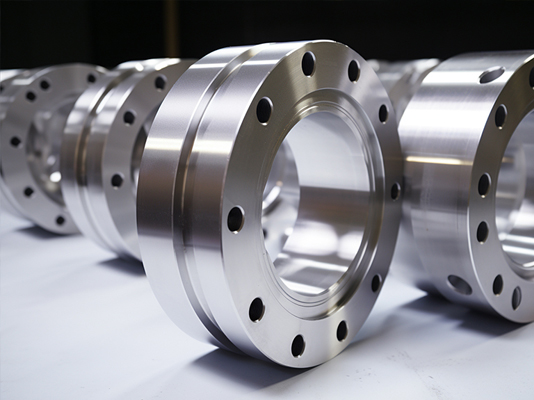

CNC Precision Parts

CNC precision parts are high-precision mechanical components produced by CNC machining…

Core Advantages

The company has an experienced technical team that focuses on product development and technological innovation. By introducing advanced automated production equipment and precision testing instruments, the company ensures high precision and high reliability of its products. The company also has independent mold design and manufacturing capabilities, and can quickly respond to customers' customized needs.

The company has established a complete quality management system and has passed international certifications such as ISO9001 and ISO14001. From raw material procurement to production and manufacturing to finished product delivery, each link undergoes strict quality inspection to ensure that the products meet international standards.

With more than 30 years of industry experience, the company has accumulated rich production experience and technical accumulation. We are familiar with the production processes of various metal products, hardware and plastic products, and can provide customers with one-stop services from design, development to mass production.

The company has multiple automated production lines with large-scale production capabilities, which can meet the needs of customers for large-volume orders. At the same time, we focus on production efficiency and cost control to ensure that we provide customers with cost-effective products.

The company's photographic equipment is exported to Europe, America, Southeast Asia, the Middle East and other regions. The aluminum alloy products, hardware and plastic products produced by the company are used in interaction with many internationally renowned brands: Leica, Hasselblad, Phase One, Canon, Nikon, Sony, Olympus, Fuji, Panasonic, Ricoh, Sigma, etc.; We are always customer-oriented, providing high-quality products and services, and have won wide market recognition.

WHY CHOOSE US

Our customer service team is always ready to surprise you with our outstanding service.

Experience

The company has multiple automated production lines and has large-scale production capabilities to meet the needs of customers for large-volume orders. At the same time, we focus on production efficiency and cost control to ensure that we provide customers with cost-effective products..

Production

The production time is fast. We do not have numerous production processes and can quickly turn drawings into actual products. The fastest production cycle is only 24 hours. We have an assembly production line that can help customers assemble products.

Processing

Having our own factory for processing, the price is more favorable. The MOQ is 1pcs. If the customer's product is still in the research and development stage, we can also support sample production and will not let the customer waste a lot of money on testing.

Assure

We have enough overseas business experience to avoid scratches and friction on products during packaging and transportation, ensuring the integrity and integrity of the products. We are also very experienced in logistics. Customers only need to sit in the office and wait for the product to be delivered

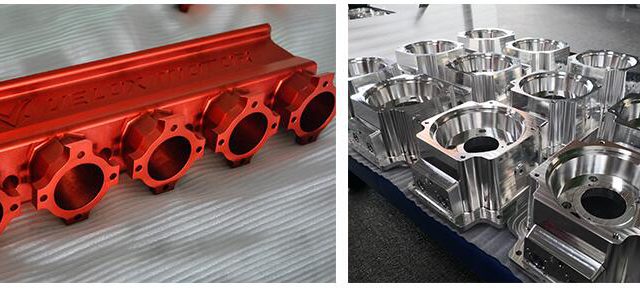

THE APPLICATIONS OF CNC MACHINING IN MECHANICAL PROCESSING

NEWS CENTER

What is the Difference Between CNC and Sheet Metal Fabrication?

In modern manufacturing, CNC machining and sheet metal fabrication are two widely used processes for producing metal components. While both techniques involve shaping and processing metal, they serve different purposes, utilize distinct methodologies, and are suited for specific applications. As a manufacturer, understanding the differences between CNC machining and sheet metal fabrication is crucial for selecting the right process to optimize production, ensure cost-effectiveness, and meet quality standards. In this article, we will explore the key differences between CNC and sheet metal fabrication,...

Applications and Types of Sheet Metal Fabrication

Sheet metal fabrication is used to create a wide range of products across various industries by cutting, bending, and joining thin, flat metal sheets, with applications including construction components like roofing, cladding, ductwork, and gutters, as well as parts for electronics, automotive, aerospace, and appliance manufacturing, utilizing materials like mild steel, brass, and aluminum depending on the desired properties; common types of sheet metal fabrication techniques include cutting, punching, bending, welding, and finishing processes to ensure durability and aesthetics.